Important index for cable's inspection---Partial discharge measurement

Important index for cable‘s inspection---Partial discharge measurement

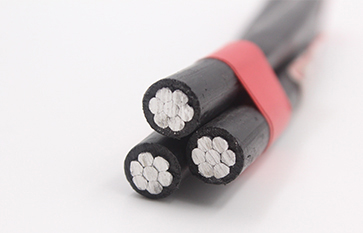

The selection of qualified wire and cable products is related to people's safety in production and life. For ordinary consumers, it is necessary to understand the conventional monitoring knowledge of wire and cable in addition to how to select the qualified wire and cable products. In the quality detection of wire and cable, there are several important indicators.

Partial discharge measurement:

There is basically no local power for the oil filled cable; even if there is a partial discharge, the oil paper cable is usually very weak as a few PC, so these cables can not measure the partial discharge in the factory test. For the extruded cable, not only is the possibility of producing partial discharge, but also the damage to plastic and rubber is more serious in the partial discharge. With the increase of voltage grade and the improvement of the working field, the problem is more serious. Therefore, the local discharge measurement should be done for the high pressure extruded cable in the factory testing.

There are many methods for measuring partial discharge. The discharge pulse can be measured according to the instantaneous charge exchange produced by the discharge, and the voltage (sound measurement method) can be measured according to the ultrasonic wave produced during the discharge, and the intensity of light can be measured according to the light produced by the discharge. The electric cable is basically used for the cable.