Important index for quality inspection of wire and cable--insulation resistance test

Important index for quality inspection of wire and cable

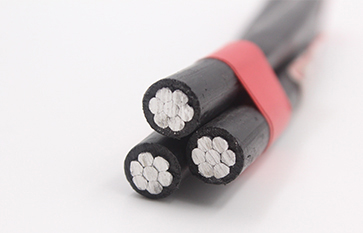

The selection of qualified wire and cable products is related to people's safety in production and life. For ordinary consumers, it is necessary to understand the conventional monitoring knowledge of wire and cable in addition to how to select the qualified wire and cable products. In the quality detection of wire and cable, there are several important indicators.

Insulation resistance test:

The insulation resistance is an important index to reflect the insulation characteristics of wire and cable products. It has a close relationship with the electrical strength, dielectric loss, and the gradual deterioration of the insulation material in the working state. For the communication cable, the low insulation resistance will increase the loop attenuation, the crosstalk between the circuits and the long distance power supply leakage on the wire core. Therefore, the insulation resistance should be higher than the specified value. Insulation resistance can be found in the process, such as insulation drying or sheath damage and damp; insulation is contaminated and mixed with conductive impurities, and the insulation layer cracking caused by various reasons. In the operation of wires and cables, insulation resistance and leakage current are often detected as the main basis for safe operation. At present, the insulation resistance measurement of wires and cables, besides ohmmeter (shake table), is commonly used by the galvanometer comparison method of high resistivity (voltage current method).